At MechTronic we have a proud history of working with apprentices and in August 2022 we welcomed two more apprentices to the team.

Since then, Alfie Lightowler, Technician Apprentice has helped design and build an OptiMate demonstration unit. This is a fully functioning replica 5-pot manifold. Every element that is on a truck is replicated within the unit, including an OptiMate electronic metering system, vapour recovery adaptor, anti-move, EB80 pneumatic control module, foot valves, vent valves and overfill prevention probes.

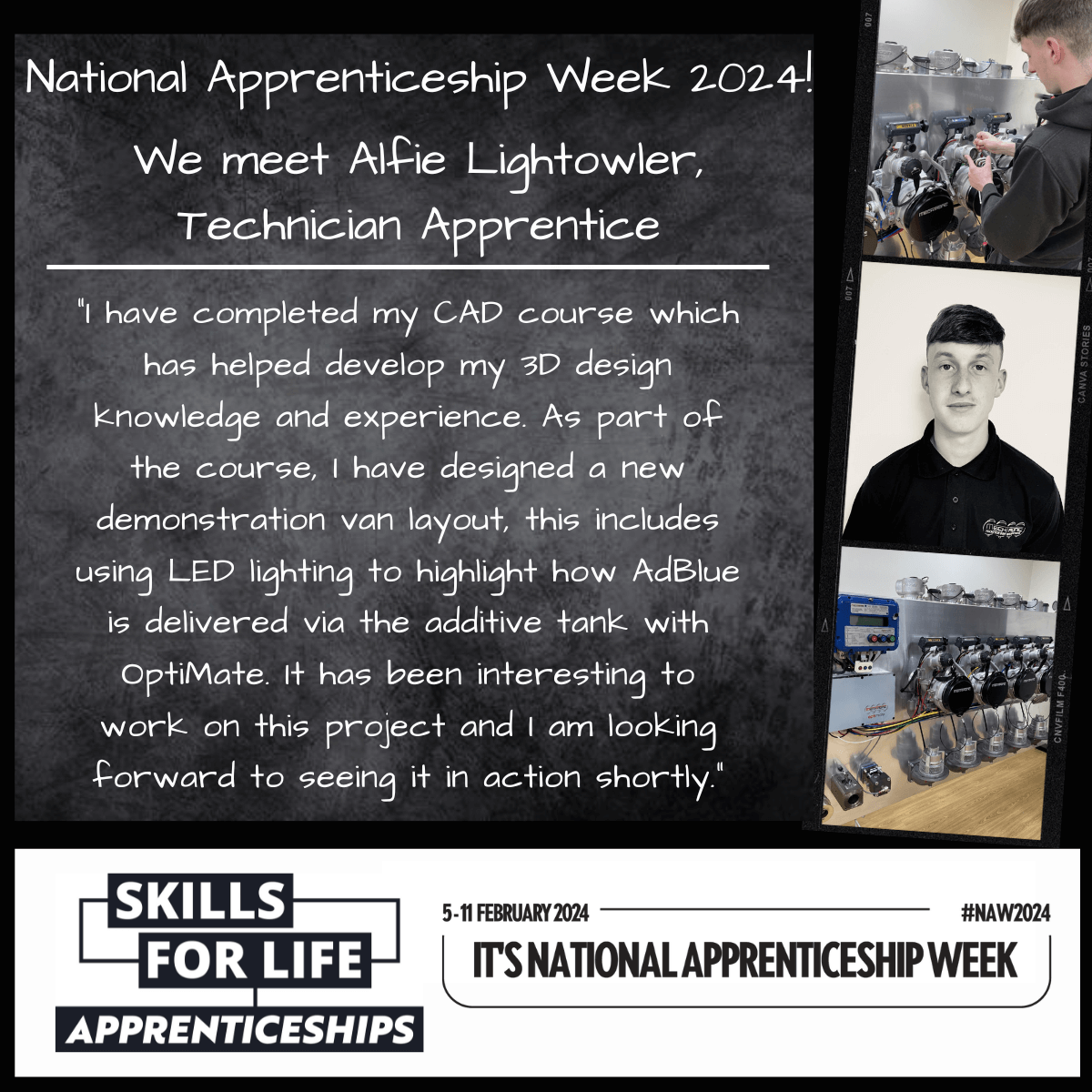

In December 2023, Alfie completed his CAD design course with Solid Works. Alfie said: “The course has helped develop my 3D design knowledge and experience. As part of the course, I have designed a new demonstration van layout, this includes using LED lighting to highlight how AdBlue is delivered via the additive tank with OptiMate. It has been interesting to work on this project and I am looking forward to seeing it in action shortly.”

Ryan Parr, Engineering and Development Manager said: “The work that Alfie has done is fantastic and has been an insightful project for him to work on. For the wider team, the OptiMate unit is a great tool, within the engineering and service team we can replicate customer issues and identify how to fix them before our engineers have arrived on site, which means that the vehicle is back on the road quicker. We can try out new firmware and ensure that updates run smoothly, we can also use this unit as a training resource for our team and as a wider demonstration system for customers who visit us in Leeds.”

What next for Alfie?

Ryan said: “Alfie will be working closely with the sales team on product development while continuing his studies. MechTronic values customer feedback, and our sales team ensure that any customer feedback is relayed to the engineering department. OptiMate was designed to be future-proof, and the company is currently working on the next development phase to ensure that it continues to provide the best service to its customers.”